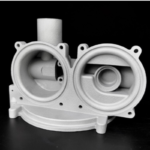

Transform Your Ideas into Precision Parts

From rapid prototyping to high-quality production, we offer on-demand 3D printing solutions with over 40 materials and 11 finishing options to meet all your design and engineering needs.

Precision. Speed. Flexibility.

Let us help you turn your vision into reality faster and more efficiently.

On-Demand Access to Precision 3D Printing Services

At AMP Precision, we provide seamless access to world-class 3D printing solutions, using cutting-edge technology and industry-leading additive manufacturing suppliers. Whether you’re prototyping, testing, or scaling up to full production, we have the materials, expertise, and capabilities to meet your needs.

3D Printing Options

At AMP Precision, we offer a wide range of 3D printing technologies and materials to suit your project’s specific requirements. Our printing solutions are flexible, allowing us to meet diverse needs from prototyping to full-scale production. Whether you need high-precision parts, durable prototypes, or complex geometries, we have the right technology for you.

White Resin

Yellow Resin

Grey Resin

Clear Resin

White Nylon PA12

TPU

AlSi10Mg

316L

Nylon PA 11

Nylon PA 11

PA 12GB

Red Wax

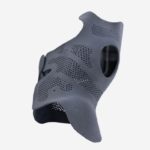

TPU (Thermoplastic Polyurethane)

Best For: Flexible, elastic parts, ideal for soft-touch or rubber-like components.

Process: FDM, SLS

Strength: High flexibility and abrasion resistance.

Black Resin

Best For: High-strength, impact-resistant parts, ideal for functional prototypes and general assembly.

Process: SLA

Strength: High tensile strength, excellent surface finish.

316L Steel

Best For: Strong, durable parts, ideal for industrial and high-strength applications.

Process: SLM, DMLS, LPBF

Strength: Exceptional hardness and tensile strength.

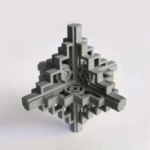

AlSi10Mg

Best For: Lightweight, high-strength components, ideal for structural and mechanical parts.

Process: SLM, DMLS, LPBF

Strength: Excellent tensile strength, high-density, and durability.

Yellow Resin

Best For: Parts requiring high impact resistance, durability, and flexibility, ideal for functional prototypes and low-volume production.

Process: SLA

Strength: Excellent toughness, high impact resistance, good dimensional stability.

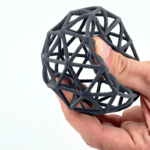

HP Nylon PA 11/PA 12

Best For: High-strength, flexible parts with excellent durability, ideal for functional prototypes and end-use parts in automotive, industrial, and aerospace applications.

Process: MJF

Strength: PA11 offers high flexibility and impact resistance, while PA12 provides excellent tensile strength, stiffness, and fatigue resistance.

Gray Resin

Best For: Parts exposed to high temperatures, ideal for functional prototypes in automotive, aerospace, and engineering applications.

Process: SLA

Strength: Exceptional heat resistance and dimensional stability.

HP Black Nylon + Fiber

Best For: Strong, lightweight parts with increased stiffness, ideal for high-performance automotive, industrial, and aerospace apps.

Process: MJF

Strength: Enhanced strength, stiffness, and durability due to carbon fiber reinforcement.

White Resin

Best For: High-precision parts with a smooth finish, ideal for prototyping, concept models, and low-volume production.

Process: SLA

Strength: Good surface finish, moderate strength, and rigidity.

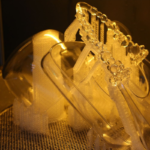

Clear Resin

Best For: Transparent parts with high detail, ideal for visual prototypes, light pipes, and models requiring clarity.

Process: SLA, DLP

Strength: Moderate strength with excellent transparency and surface finish.

Applications

3D printing services are widely applicable across multiple industries, including but not limited to:

Product Prototyping

Medical Devices

Aerospace

Education and Research

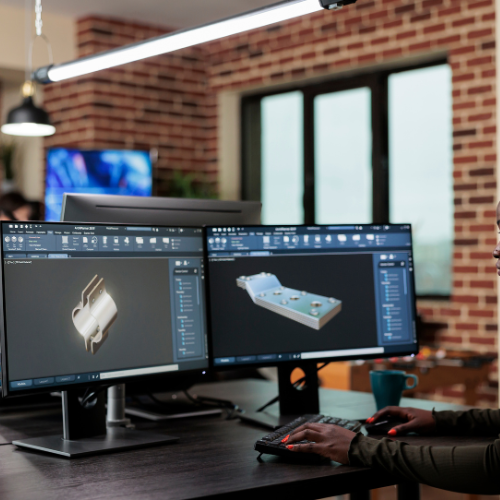

Design and Engineering Support

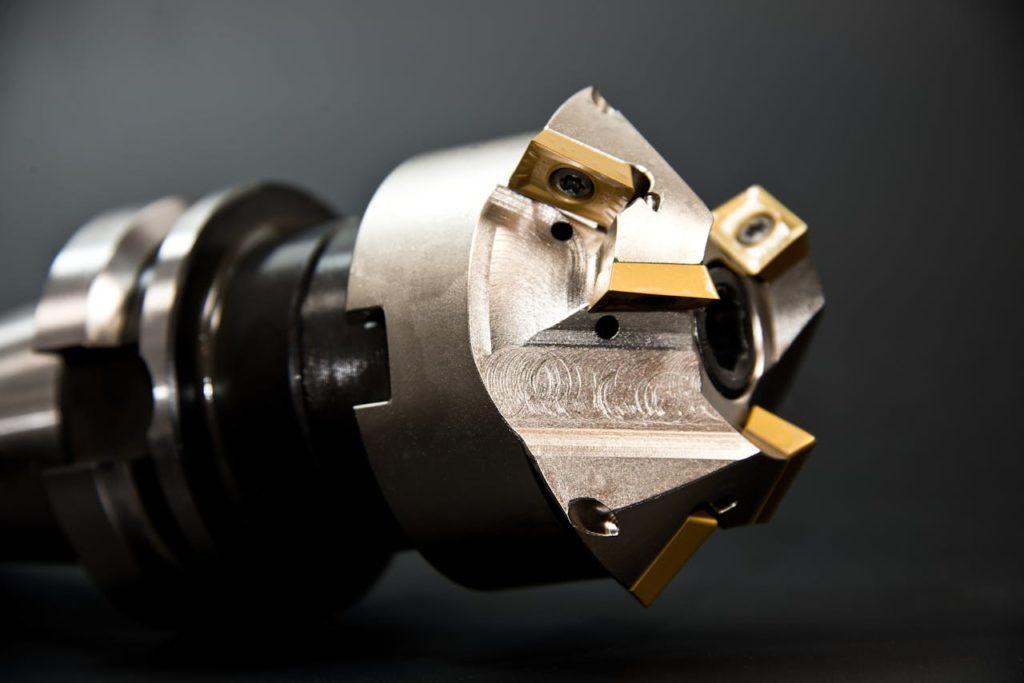

AMP offers comprehensive design and engineering support services. Our professional team assists clients through every stage, from concept to final product, ensuring manufacturability and efficiency throughout the printing process.

We support various CAD file formats and provide design optimization suggestions to maximize printing quality and efficiency.

Quality Control

At AMP, we emphasize quality control for every 3D printing project. Each printed part undergoes rigorous quality inspections during production to ensure dimensions, shapes, and surface finishes meet client specifications.

We employ advanced measurement tools and equipment to guarantee consistency and reliability in every component.

Fast Delivery and Flexible Production

We understand the market’s demand for quick delivery, especially in prototyping and small-batch production scenarios. AMP’s production processes are flexible, allowing us to respond swiftly to client orders, whether for custom one-off pieces or bulk production, ensuring timely delivery.

Choosing the Right 3D Printing Service

Understand Available Technologies

Familiarize yourself with 3D printing technologies available on the market, including FDM, SLA, SLS, DLP, MJF, and SLM. Research how each works, its pros, cons, and the types of materials it supports.

Cost Considerations

Understand the cost implications of each 3D printing technology. Consider equipment costs, material costs, post-processing requirements, and overall production time.

Scalability & Production Volume

Evaluate the scalability and production volume requirements of your project. Some technologies are better suited for small-scale prototyping, while others excel in large-scale production.

Testing & Iteration

Before committing to full-scale production, conduct small-scale tests or prototyping using the selected technology. This will help validate its suitability for your project and allow for necessary adjustments before proceeding.

Assess Project Requirements

- Size: Consider the size of your object, as some technologies have build volume limits.

- Complexity: For intricate designs, choose a technology that offers high resolution and precision.

- Materials: Ensure the technology supports the materials your project requires, such as plastic, metal, or resin.

- Strength and Durability: Consider the mechanical performance and strength needed for your object.

- Surface Finish: If surface smoothness is critical, select a technology known for producing high-quality finishes.

- Speed: Consider the production speed. Some technologies are faster than others, but this may come at the expense of resolution or material options.

Cost Considerations

Understand the cost implications of each 3D printing technology. Consider equipment costs, material costs, post-processing requirements, and overall production time.

Scalability & Production Volume

Evaluate the scalability and production volume requirements of your project. Some technologies are better suited for small-scale prototyping, while others excel in large-scale production.

Testing & Iteration

Before committing to full-scale production, conduct small-scale tests or prototyping using the selected technology. This will help validate its suitability for your project and allow for necessary adjustments before proceeding.

Evaluate Print Quality

Examine sample prints or prototypes created using the different 3D printing technologies you’re considering. Evaluate the print quality, accuracy, level of detail, and surface finish. Pay attention to layer resolution, dimensional accuracy, and ability to capture intricate details.

Cost Considerations

Understand the cost implications of each 3D printing technology. Consider equipment costs, material costs, post-processing requirements, and overall production time.

Scalability & Production Volume

Evaluate the scalability and production volume requirements of your project. Some technologies are better suited for small-scale prototyping, while others excel in large-scale production.

Testing & Iteration

Before committing to full-scale production, conduct small-scale tests or prototyping using the selected technology. This will help validate its suitability for your project and allow for necessary adjustments before proceeding.

Consider Material Options

Different 3D printing technologies support specific materials. Determine the material properties your project requires, such as strength, flexibility, heat resistance, transparency, or biocompatibility. Ensure the technology you choose can work with these materials.

Cost Considerations

Understand the cost implications of each 3D printing technology. Consider equipment costs, material costs, post-processing requirements, and overall production time.

Scalability & Production Volume

Evaluate the scalability and production volume requirements of your project. Some technologies are better suited for small-scale prototyping, while others excel in large-scale production.

Testing & Iteration

Before committing to full-scale production, conduct small-scale tests or prototyping using the selected technology. This will help validate its suitability for your project and allow for necessary adjustments before proceeding.

Why Choose AMP's 3D Printing Services?

By choosing AMP’s 3D printing services, you will receive professional technical support, high-quality products, and efficient delivery services. We are committed to helping you stand out in the competition through innovative printing technologies and continuous improvement. Whatever your project needs may be, AMP is your trusted partner.