Anodizing

A comprehensive guide to anodizing, its benefits, processes, and applications across industries.

What is Anodizing?

Anodizing is an electrochemical process used to increase the thickness of the natural oxide layer on the surface of metal parts, primarily aluminum. This process not only enhances the material's durability but also provides a decorative finish.

Unlike paint or plating, anodizing integrates with the underlying aluminum, ensuring a durable and wear-resistant surface. It is commonly used in industries requiring high-performance and aesthetic finishes.

Benefits of Anodizing

- Corrosion Resistance: Provides a robust barrier against environmental factors.

- Aesthetic Versatility: Offers a wide range of colors and textures.

- Durability: Increases wear and scratch resistance.

- Lightweight Solution: Ideal for applications where weight matters, such as aerospace.

Types of Anodizing

There are several types of anodizing, each tailored for specific applications:

- Type I (Chromic Acid Anodizing): Provides a thin, protective layer suitable for aerospace applications.

- Type II (Sulfuric Acid Anodizing): The most common form, offering both protection and decorative finishes.

- Type III (Hard Anodizing): Produces a thicker, harder oxide layer for extreme wear resistance.

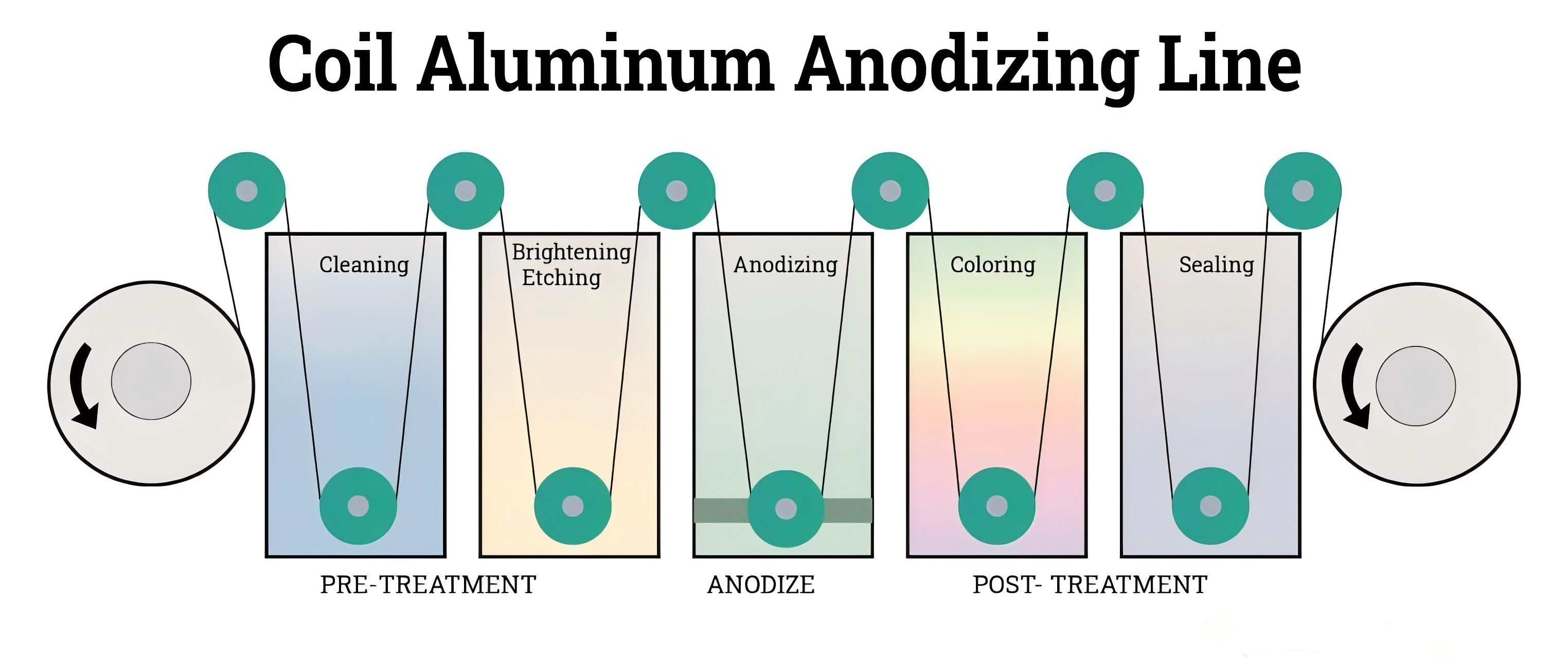

The Anodizing Process

The anodizing process involves multiple stages to ensure optimal quality:

- Preparation: Cleaning and degreasing to remove impurities.

- Anodizing: Submerging the metal in an electrolyte solution, usually sulfuric acid, and applying an electric current.

- Coloring (Optional): Adding dyes to achieve desired colors.

- Sealing: Treating the surface to lock in the oxide layer for durability.

Applications

Anodizing is widely utilized across various industries, including:

- Aerospace: For lightweight and corrosion-resistant components.

- Architecture: Provides durable and decorative building materials.

- Consumer Electronics: Ensures sleek and stylish finishes for devices.

- Automotive: Protects and enhances exterior and interior parts.

Frequently Asked Questions

Q: Is anodizing environmentally friendly?

A: Yes, anodizing uses non-toxic substances and generates minimal waste compared to other surface treatments.

Q: Can anodized surfaces be repaired?

A: Anodized layers are permanent but can sometimes be re-treated depending on the damage.