Advanced CNC Milling Solutions for Precision and Quality

- Machining Dimensions Up to 84 x 40 x 30 in, Lead Times from 5–22 Days

- Multi-Axis CNC Milling for Complex Geometries and Detailed Work

- Precision Tolerances to ±0.001 in, Extensive Material Options

- Wide Range of Metals and Plastics for Custom Solutions

What is CNC Milling?

CNC Milling (Computer Numerical Control Milling) is a precise manufacturing process that uses computer-controlled, multi-axis rotary cutters to remove material from a workpiece. This automated process allows for efficient, repeatable, and highly accurate production of parts and components with intricate geometries and fine details, making it ideal for both prototypes and high-volume production runs.

How CNC Milling Works?

The CNC milling process begins with CAD (Computer-Aided Design) files, which our team uses to program the CNC milling machine. The software translates these digital designs into a series of commands that guide the machine’s multi-axis movements. During milling, the rotating cutting tool moves along multiple axes (typically 3, 4, or 5), carving out material to match the design specifications. This simultaneous movement in multiple directions allows for greater flexibility, precision, and speed in creating complex shapes.

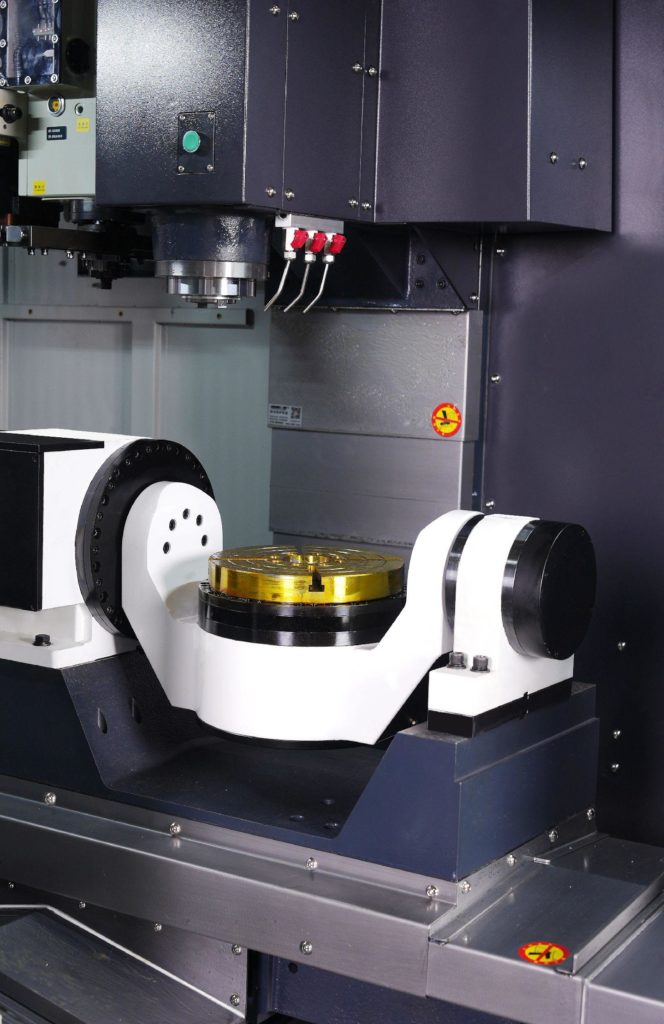

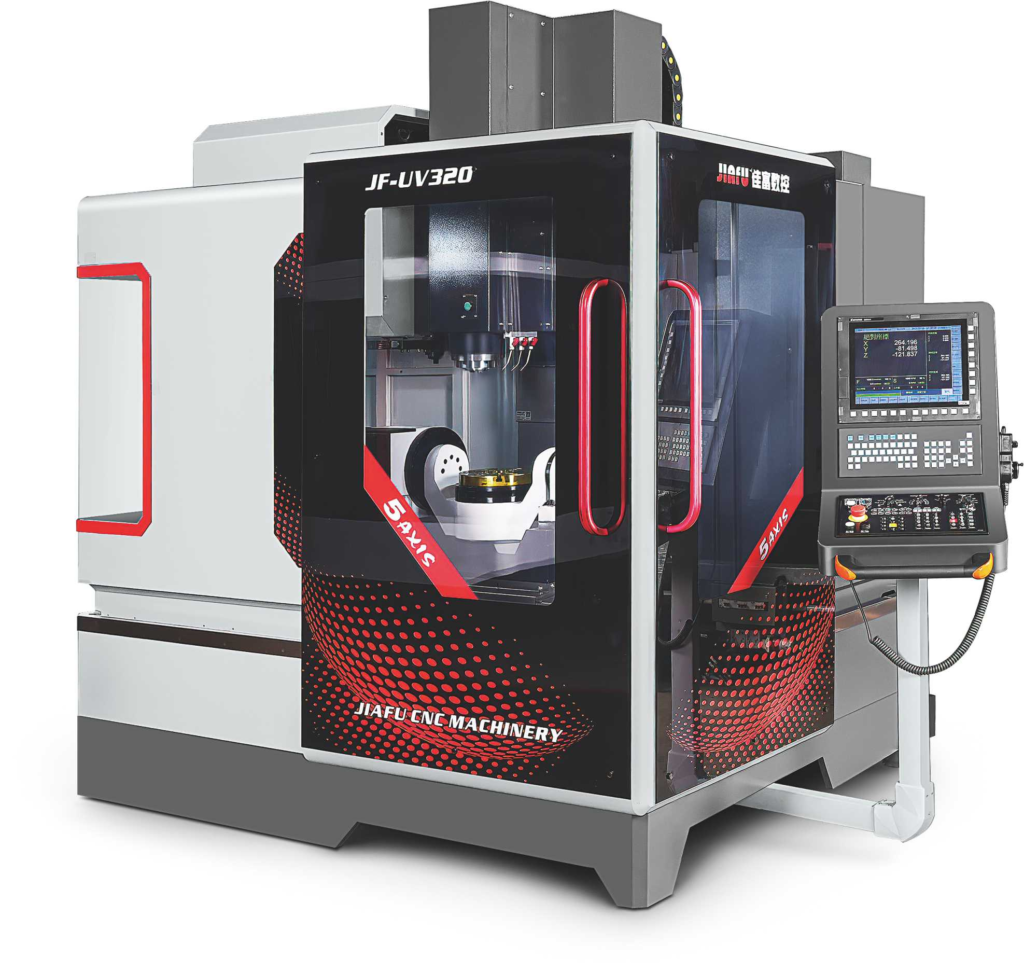

Our CNC Milling Equipment

At AMP, we utilize the latest high-speed CNC milling machines equipped with multi-axis capabilities to handle even the most complex machining needs. Our advanced equipment includes features like:

- Multi-axis milling capabilities: From 3-axis to 5-axis machines, enabling complex, multi-directional machining.

- High-speed spindles: Allowing faster cutting speeds and improved surface finish on each component.

- Wide material compatibility: Milling equipment can handle materials such as aluminum, stainless steel, titanium, and engineering plastics, making it adaptable for various industries.

This cutting-edge technology enables us to maintain high production efficiency and meet tight tolerances, essential for high-precision parts.

CNC Machine Capabilities

- Lead Time: 5 – 22 days, depending on project requirements.

- Work Envelope: Up to 84 x 40 x 30 in (2134 x 1016 x 762 mm)

- General Tolerances:

- Metals to ISO 2768 or ±0.005 in (±0.127 mm)

- plastics and composites to ±0.010 in (±0.254 mm)

- Precision Tolerances: Sub-±0.001 tolerances, per your specifications and GD&T.

- Threads: All standard thread sizes and custom thread machining upon request

- Milling Options: Vertical, Horizontal, 3-Axis, 4-Axis, 5-Axis, and multi-axis mill-turn for advanced precision.

Materials We Machine

- Metals: Aluminum, stainless steel, carbon steel, copper, titanium, tool steel, and high-temperature alloys like Inconel.

- Plastics: ABS, acrylic, acetal, PEEK, polycarbonate, Teflon/PTFE, and Ultem.

- Other: G-10 composites, Macor ceramics, and various wood types.

For materials not listed, our team can source and machine to custom specifications upon request.

Al6061 Bar

Copper Bar

Plastic Plate

Other Manufacturing Capabilities

At AMP Precision, we offer a comprehensive range of CNC manufacturing services beyond CNC milling, ensuring that we meet diverse project needs.

Why Choose Us?

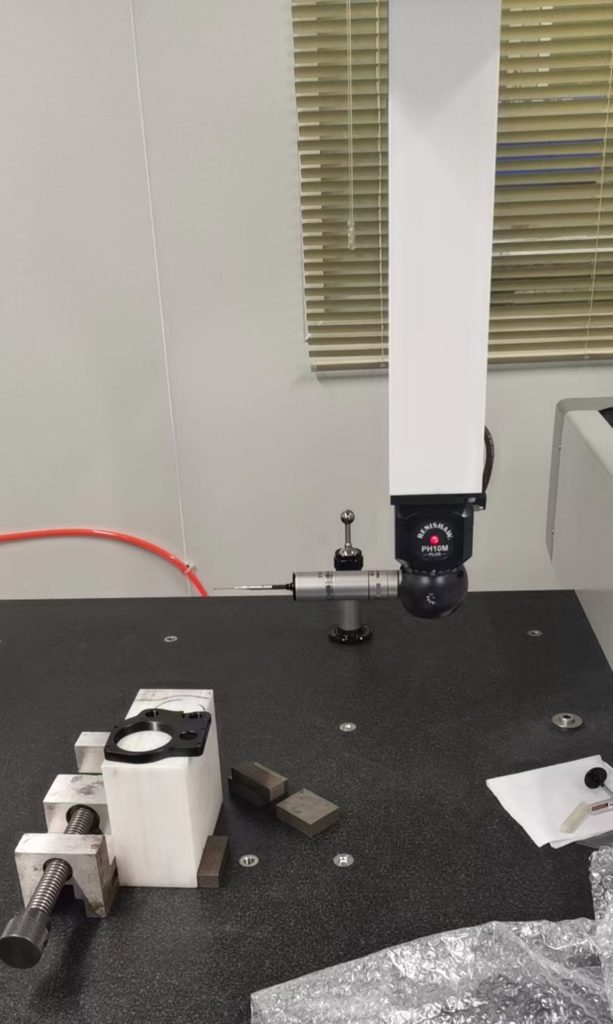

With Amproto Precision’s CNC Milling Services, clients receive the benefits of advanced machining technology, a skilled engineering team, and strict quality control. From initial design support to final production, AMP offers end-to-end CNC milling solutions that ensure every component meets the highest standards of accuracy and reliability.

Applications

Our CNC milling services are integral to industries requiring precision and complexity, including:

Aerospace: Milling lightweight but strong parts with high structural integrity.

Automotive: Producing accurate components for engines and frames, enhancing durability.

Optics: Crafting precise parts for optical instruments, lens housings, and more.

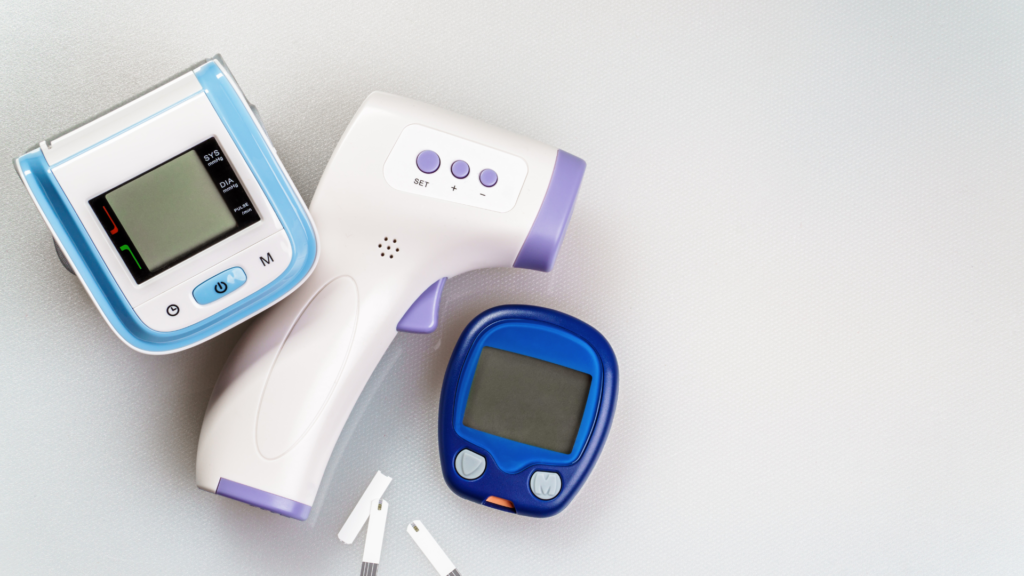

Medical Devices: Manufacturing complex parts that meet stringent quality and precision standards.

Our Amazing Clients