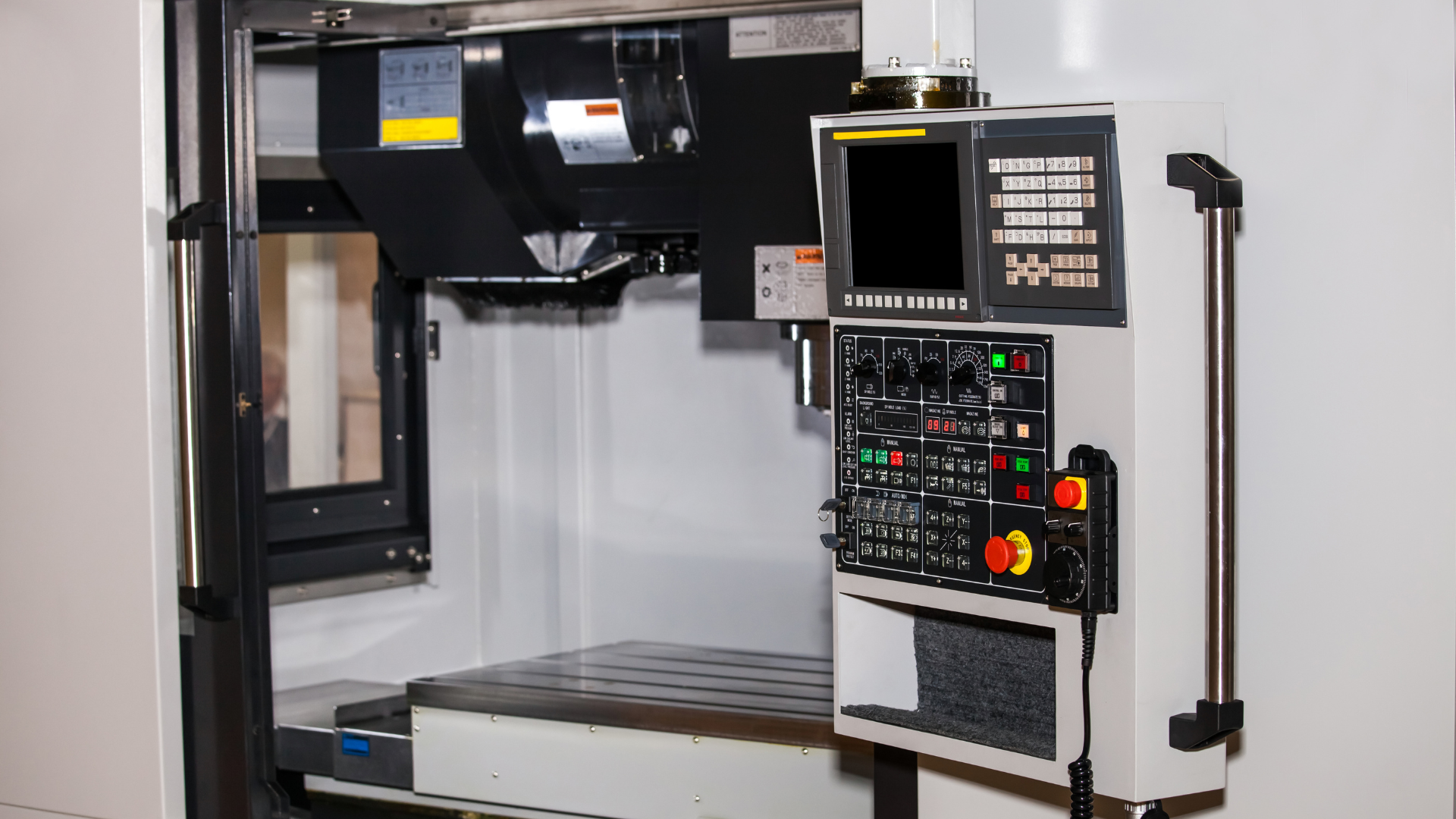

In the modern watchmaking industry, precision and innovation are key to success. As a core technology in manufacturing, CNC (Computer Numerical Control) precision machining redefines the possibilities of watch production. CNC machining can significantly enhance design freedom, production efficiency, and product quality for brands launching new watch series.

1. Enhancing Design Freedom

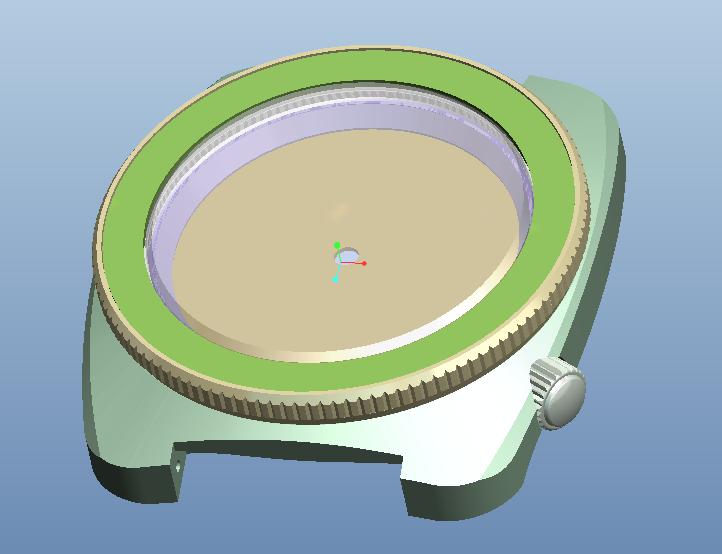

CNC technology allows for the creation of complex geometries and intricate details, enabling designers to fully realize their creative visions. From unique case shapes to intricate dial textures, CNC machining can achieve designs that traditional methods find challenging. For instance, CNC machining can easily create skeletonized dials, adding depth and sophistication to a watch.

Moreover, for specialized materials like titanium alloys, carbon fiber, or Damascus steel, CNC machining offers precise control, ensuring that each product meets both functional and aesthetic expectations.

2. Optimizing Production Efficiency

CNC precision machining enables a fast and accurate production process through digital design and manufacturing. Compared to traditional hand-finishing or mold-casting methods, CNC machining significantly shortens production time, especially for small-batch custom manufacturing.

For example, when developing a new watch series, CNC can be used to create prototype products quickly to validate design feasibility. Once the design is finalized, CNC machines can seamlessly transition to batch production, dramatically reducing the time to market.

3. Improving Product Quality

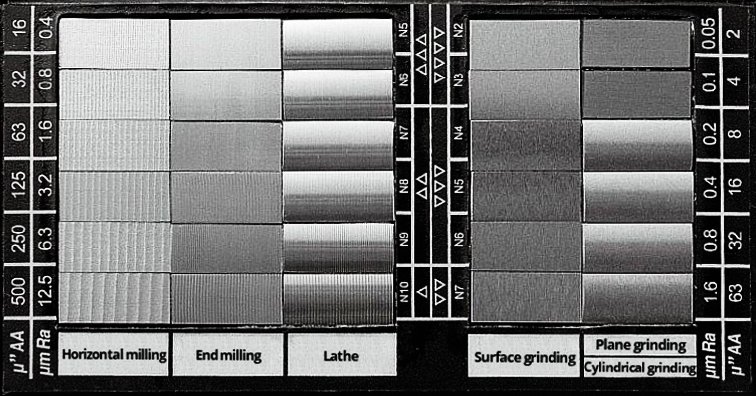

CNC machining is renowned for its exceptional precision and consistency. For watches, where every component’s accuracy directly impacts overall quality and performance, CNC machining ensures tolerances are controlled at the micron level, guaranteeing stability and durability.

Additionally, CNC technology facilitates seamless manufacturing processes, such as producing monobloc cases, which enhance water resistance and minimize assembly errors.

4. Reducing Development Costs

While the initial investment in CNC equipment may be high, it can reduce overall costs during new watch series development by eliminating mold development expenses and lowering labor costs. Furthermore, CNC machining’s precision and low rework rates help minimize waste during production.

5. Achieving Personalized Customization

With growing consumer demand for personalization, watch brands require more flexible production methods. CNC machining supports small-batch production and high customization, enabling quick adjustments to designs and specifications based on customer needs. For example, when launching a new series, brands can offer high-end clients options for engraving, unique patterns, or customized components.

CNC precision machining, with its efficiency, precision, and flexibility, is helping manufacturers break the limitations of traditional production methods. If you’re seeking solutions for developing a new watch series, consider integrating CNC machining into your production process. This technology can inject new vitality into your brand and help your products stand out in the market.

To learn more about CNC machining and how it can transform your watchmaking process, feel free to contact us. Share your vision, and let’s craft exceptional timepieces together.