AMP Precision CNC Turning Services

High Precision | Fast Delivery | Custom Solutions

Why Choose Our CNC Turning Service?

- Repeatability: Consistent results for every part, ensuring mass production reliability.

- Dimensional Precision: Our CNC processes guarantee parts meet strict specifications.

- Custom Solutions: From prototypes to large runs, we meet all your manufacturing needs.

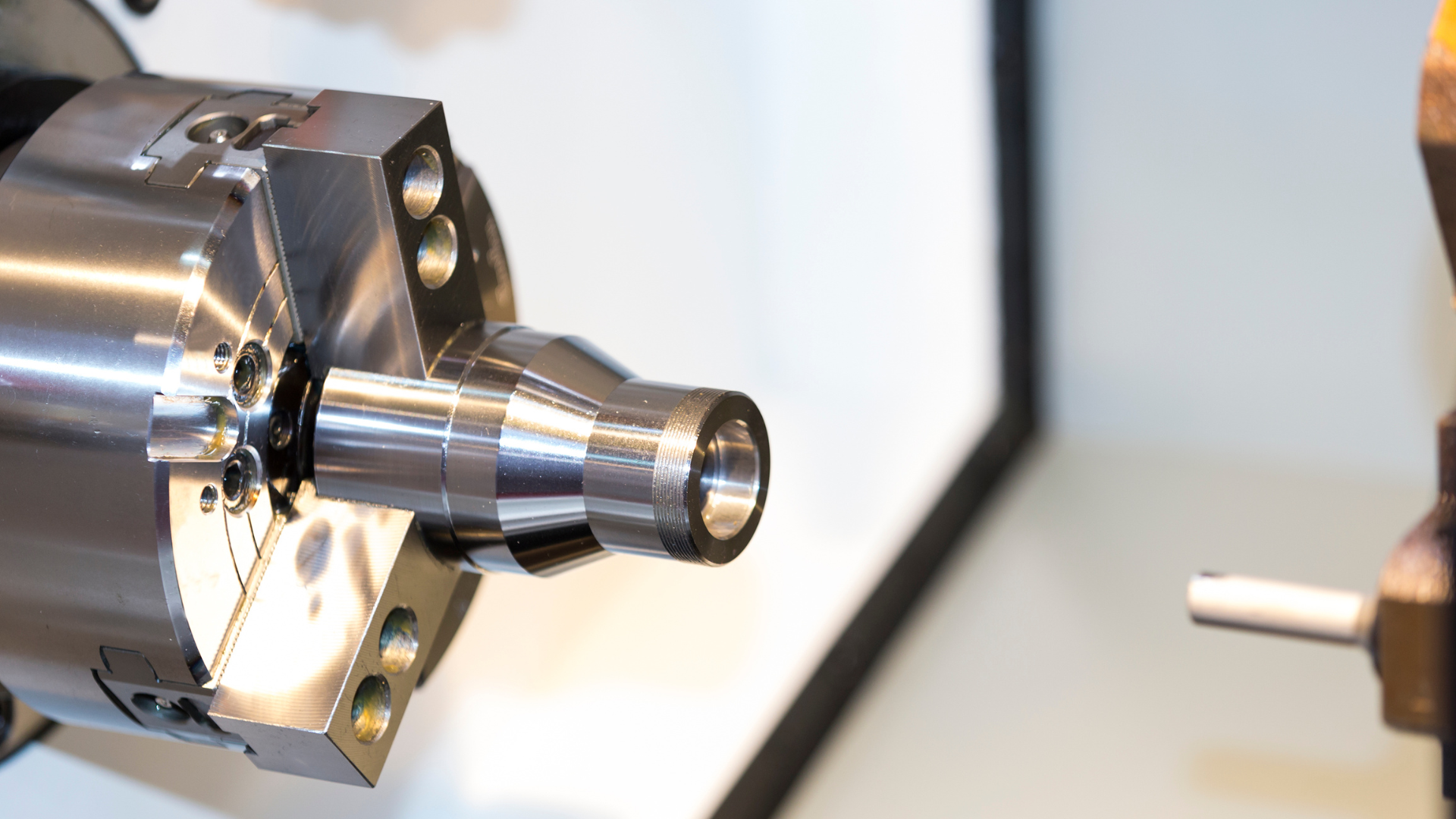

What Is CNC Turning?

CNC Turning is a subtractive manufacturing process that utilizes a CNC lathe to shape a workpiece by rotating it against stationary cutting tools. This method is ideal for producing complex cylindrical parts with tight tolerances. At AMP Precision, we leverage advanced CNC lathes equipped with live tooling, allowing us to perform both turning and milling operations in a single setup, enhancing versatility and efficiency.

How CNC Turning Works?

The CNC turning process begins with a CAD design that guides the CNC machine. The workpiece is clamped onto a rotating spindle, and as it turns, the cutting tool shapes the material according to the design specifications. Our advanced multi-axis CNC lathes enable simultaneous movements along multiple axes, allowing for intricate geometries and high-precision cutting. This technology supports high-speed machining, which reduces production times without compromising quality.

Our CNC Turning Equipment

AMP’s state-of-the-art CNC lathes are equipped to handle various materials and produce components with exceptional precision. Key features of our CNC turning equipment include:

- Multi-axis turning capabilities: Enables complex part geometries and faster production.

- High-speed spindles: Ensures rapid and accurate cutting for improved efficiency.

- Material versatility: Handles metals like aluminum, stainless steel, and titanium, as well as specialized materials like engineering plastics.

This technology enables us to deliver high-quality, intricate components suitable for a variety of industries.

CNC Turning Capabilities

- Lead Time: 5 – 22 Days

- Max Diameter: 13.75 in (349.3 mm)

- Max Swing Length: 36 in (914.4 mm)

- Metals: ISO 2768 standards or ± 0.005 in (± 0.127 mm)

- Plastics: ± 0.010 in (± 0.254 mm)

- Precision Torelance: sub ± 0.001 in, based on your specifications and GD&T requirements.

- Thread Capabilities: We accommodate standard thread sizes and can machine custom threads upon manual review.

Materials We Work With

- Metals: Aluminum, Stainless Steel, Steel, Inconel, Titanium, Tool Steel

- Plastics: ABS, Nylon, PEEK, Polycarbonate

- Other Materials: Machined Ceramics, G-10, Wood

If your project requires materials not listed, let us know! We can accommodate special requests.

Aluminum Bar

Copper Bar

Plastic Bar

Design Recommendations for CNC Turning

Designing components for CNC turning requires careful consideration. Key factors include:

- Material Selection: Different materials may require unique tooling or cutting techniques.

- Component Size and Shape: Ensure designs are compatible with machine capabilities.

- Orientation: Optimize part orientation for machining efficiency.

- Tolerances and Finishes: Specify desired tolerances and surface finishes early in the design process.

Other Manufacturing Capabilities

At AMP Precision, we offer a comprehensive range of CNC manufacturing services beyond CNC turning, ensuring that we meet diverse project needs.

Why Choose Us

With Amproto Precision’s CNC Turning Services, clients receive the benefits of advanced machining technology, a skilled engineering team, and strict quality control. From initial design support to final production, AMP offers end-to-end CNC turning solutions that ensure every component meets the highest standards of accuracy and reliability.

Our Amazing Clients